|

|

|

On Board Air - Air Conditioner Conversion

with Bill Johnston

When you have old air conditioning parts

in the garage and an air tank sitting there staring you in the face, what do

you do? You build an On Board Air System! I wanted to make it simple yet

functional. I also wanted mount everything out of the way so it didn't look

too jumbled under the hood. This will provide a way to air up the tires

after a trail or even provide air for an air locker.

|

|

|

The

first part was simple, just bolting the air conditioner compressor into

place with factory brackets and adding a new belt to link it to the factory

double row crank pulley. If you can find factory hoses it will make the

installation easier and less expensive. The

first part was simple, just bolting the air conditioner compressor into

place with factory brackets and adding a new belt to link it to the factory

double row crank pulley. If you can find factory hoses it will make the

installation easier and less expensive. |

As

you can see we attached the factory hoses for the air output (next to block)

and intake (closer to fender) and routed them over to the fender. This

retains a very stock look while most folks won't realize the hoses no longer

point in the direction the factory intended. We (carefully) took some of the

bend out of the metal hose ends to direct the hoses away from the hot

exhaust manifold. As

you can see we attached the factory hoses for the air output (next to block)

and intake (closer to fender) and routed them over to the fender. This

retains a very stock look while most folks won't realize the hoses no longer

point in the direction the factory intended. We (carefully) took some of the

bend out of the metal hose ends to direct the hoses away from the hot

exhaust manifold. |

We

ran the hoses to two new components. The intake hose connects to some brass

fittings that have an inline oiler mounted at a 90 degree angle. This lets

us monitor the oil level instead of letting the oiler disappear into the

fender. The air conditioning compressor is normally lubricated by the gases

in a continuously circulating air conditioning system. Because we are not

using a closed loop system, we have to constantly supply lubrication to the

compressor to keep it from burning up. The oil will be removed from the

system farther down the line. We

ran the hoses to two new components. The intake hose connects to some brass

fittings that have an inline oiler mounted at a 90 degree angle. This lets

us monitor the oil level instead of letting the oiler disappear into the

fender. The air conditioning compressor is normally lubricated by the gases

in a continuously circulating air conditioning system. Because we are not

using a closed loop system, we have to constantly supply lubrication to the

compressor to keep it from burning up. The oil will be removed from the

system farther down the line. |

The

black box looking component attached to the output hose is a one-way valve

that will keep the air pressure in the rest of the system from being forced

back into the compressor after it turns off. This will extend the life of

the seals in the air compressor. The

black box looking component attached to the output hose is a one-way valve

that will keep the air pressure in the rest of the system from being forced

back into the compressor after it turns off. This will extend the life of

the seals in the air compressor.The air tank started life as an oxygen

tank that we found in a yard sale for $10. When we found it, it still had

about 3000 psi of oxygen in it, so using this tank in a system that will

never see more than 150 psi is overkill the price was right. the brackets

are just aluminum blocks drilled out to fit the bottle. |

|

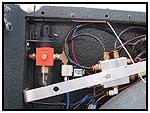

We hid some of the components out of harms way, all the

way back near the air tank. The aluminum block (manifold) seen here sends

air pressure to a 150 psi air pressure pop-off valve, a pressure switch that

turns off the system when the pressure hits 120 psi, and an air regulator

with a water/oil separator for pressure controlled output such as an air

locker. This is all protected by an interior panel. Out of sight, out of

mind. We hid some of the components out of harms way, all the

way back near the air tank. The aluminum block (manifold) seen here sends

air pressure to a 150 psi air pressure pop-off valve, a pressure switch that

turns off the system when the pressure hits 120 psi, and an air regulator

with a water/oil separator for pressure controlled output such as an air

locker. This is all protected by an interior panel. Out of sight, out of

mind. |

|

|

| We also added a small aluminum block (manifold)

at the tailgate for a quick disconnect. This is where we will attach our air

line to fill the tires with.

To monitor the air pressure in the system, we found a dual needle air

gauge from a bus. This allows us to see how much pressure is in the system

as well as how much pressure is in the regulated feeder line. |

|

|

The feeder line is run through an air regulator

that is set for 90 psi as you can see on the gauge in the picture on the far

right. The whole system is turned on just as you would turn on the air

conditioner. Turn on the fan and hit the 'AC' button!

This was originally an

AC equipped vehicle so the wiring was still there from the factory. This was originally an

AC equipped vehicle so the wiring was still there from the factory.

This is not a critical system to have when out on the trail, until you

need it. Many times you will find others on the trail with you that have air

you can use to re-inflate that spare, or air up all of your tires at the end

of a good trail ride. But it feels good to be able to do it yourself. |