|

|

ARB

Track/Kick Rear Air Locker Project Sidewinder/ARB part 2 with Bill Johnston

ARB has an air locker to fit both ring and pinion combinations that are found in the rear diffs from 1988 and up. From 1988 to 1993 Suzuki used a 10 bolt ring, this uses ARBs RD74 model. In 1993, Suzuki started putting a 12 bolt model into the rear differential. This is what we were working with, so ARB supplied the RD79 model for this installation. Both flavors of ring gear were used in 1993, so if you have any question as to what you have, there is a quick way to find out without pulling the whole thing apart.

Let me start by saying that if you are not comfortable with working on your own gearing, this is probably not the place to start unless you have someone with a little experience showing you how. If you don't set the backlash correctly, or you end up with spare parts... it will get expensive fast. |

||

That

said, we started with the third member bolted to the workbench. Before

disassembly, we marked the bearing caps with a punch and then marked the

third member casing to match. One dot for the left side and two dots for

the right. That

said, we started with the third member bolted to the workbench. Before

disassembly, we marked the bearing caps with a punch and then marked the

third member casing to match. One dot for the left side and two dots for

the right. |

|||

Next

we removed the caps and set them aside. Notice the cool tool I used to

hold everything steady... I found that a birfield stub has 26 splines,

just like the rear axle. I keep two grenaded birfield stubs with my 'specialty'

tools for working with rear differentials. They are easy to hold onto and

they allow you to easily turn the splines on the bench. Next we just lift

the carrier out of the casing and move the casing to the floor. Next

we removed the caps and set them aside. Notice the cool tool I used to

hold everything steady... I found that a birfield stub has 26 splines,

just like the rear axle. I keep two grenaded birfield stubs with my 'specialty'

tools for working with rear differentials. They are easy to hold onto and

they allow you to easily turn the splines on the bench. Next we just lift

the carrier out of the casing and move the casing to the floor. |

|||

The

bearings on this carrier were in excellent shape, so we decided to reuse

them. We removed them easily using a bearing puller. Make sure you get the

ends of the arms all the way under the center portion of the bearing or

you could just rip the outer cage off - thus destroying the bearing. The

bearings on this carrier were in excellent shape, so we decided to reuse

them. We removed them easily using a bearing puller. Make sure you get the

ends of the arms all the way under the center portion of the bearing or

you could just rip the outer cage off - thus destroying the bearing. |

|||

Flip

the carrier over and repeat the procedure on the other bearing. Here you

can see the 12 bolts holding the ring on the carrier. You can also see the

teeth that the speed sensor (mentioned above) counts in the photo to the

right. After reassembly, you will no longer have those teeth to worry

about. Flip

the carrier over and repeat the procedure on the other bearing. Here you

can see the 12 bolts holding the ring on the carrier. You can also see the

teeth that the speed sensor (mentioned above) counts in the photo to the

right. After reassembly, you will no longer have those teeth to worry

about. |

|||

Next

we remove the ring gear bolts and carefully remove the ring gear, setting

it aside. Next

we remove the ring gear bolts and carefully remove the ring gear, setting

it aside. |

|||

Now

we turn our attention to the ARB Air Locker. You will notice when you

press the bearings back on that one of the bearing journals is longer than

the other. This is the way they get the air into the center of the

carrier... The journal is plumbed to move air from a seal housing on the

longer section - into the heart of the carrier. This is the side that

should be facing up when you put the ring gear back on. Now

we turn our attention to the ARB Air Locker. You will notice when you

press the bearings back on that one of the bearing journals is longer than

the other. This is the way they get the air into the center of the

carrier... The journal is plumbed to move air from a seal housing on the

longer section - into the heart of the carrier. This is the side that

should be facing up when you put the ring gear back on. |

|||

Looking

closer at the new carrier, you will notice that the flange thickness is as

thick as the old carrier (with the speed sensor gear). Since you will be

using the new carrier, the sensor gear will not be a part of the assembly.

Tighten

the bolts in a cross pattern and finish up with a torque wrench. Looking

closer at the new carrier, you will notice that the flange thickness is as

thick as the old carrier (with the speed sensor gear). Since you will be

using the new carrier, the sensor gear will not be a part of the assembly.

Tighten

the bolts in a cross pattern and finish up with a torque wrench. |

|||

The

Factory Service Manual recommends that the ring gear (aka - drive bevel

gear) bolts get torqued to 58-66 ft-lbs. The

Factory Service Manual recommends that the ring gear (aka - drive bevel

gear) bolts get torqued to 58-66 ft-lbs.

Next you have to find the best location for the air line to enter the case. The key is to keep it away from the gears, but still make sure it clears the axle housing when the third member reinstalled. |

|||

After

marking the best location with a punch, we drilled a pilot hole and then

followed it up with the 7/16" drill bit for a final hole. After

marking the best location with a punch, we drilled a pilot hole and then

followed it up with the 7/16" drill bit for a final hole. |

|||

You

can see the final location once we cleaned up the hole. This is going to accommodate

a 1/4" NPT fitting, so the next step is to tap it with the

correct type of tap. This is a thin section of the case, so you don't want

to have to do this twice and run the risk of making the hole too large. You

can see the final location once we cleaned up the hole. This is going to accommodate

a 1/4" NPT fitting, so the next step is to tap it with the

correct type of tap. This is a thin section of the case, so you don't want

to have to do this twice and run the risk of making the hole too large. |

|||

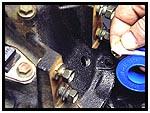

Teflon

tape should be a staple in a toolbox. Seal the threads well and install

the fitting in the new tapped location. This seal isn't for air, the

system never pressurizes the axle housing. This is more to keep all the

lubricant in the housing if you get a little radical on the trails. Teflon

tape should be a staple in a toolbox. Seal the threads well and install

the fitting in the new tapped location. This seal isn't for air, the

system never pressurizes the axle housing. This is more to keep all the

lubricant in the housing if you get a little radical on the trails. |

|||

No

one likes an oil leak, especially when you were the one that did the

drilling... No

one likes an oil leak, especially when you were the one that did the

drilling...

Don't torque it down too much, remember that you want it to seal without stripping out the new threads. |

|||

Now

that the bulkhead body (correct name) is installed in the housing, it is

time to work on the tube that gets the air from the fitting to the locker.

Start with selecting the correct compression nut and ferrule. There are

two ferrules that come with the installation kit, but only one of them

will fit correctly on the tube. See the photo to the right. Now

that the bulkhead body (correct name) is installed in the housing, it is

time to work on the tube that gets the air from the fitting to the locker.

Start with selecting the correct compression nut and ferrule. There are

two ferrules that come with the installation kit, but only one of them

will fit correctly on the tube. See the photo to the right. |

|||

Putting

the carrier back into place, use your hands or an appropriately sized

tubing bender to form the tube up and over the bearing cap and around the

carrier body. The seal housing (the ring on the end of the tubing) will

end up oriented with the tube coming up just to the right of the locking

tab on top of the bearing cap. Putting

the carrier back into place, use your hands or an appropriately sized

tubing bender to form the tube up and over the bearing cap and around the

carrier body. The seal housing (the ring on the end of the tubing) will

end up oriented with the tube coming up just to the right of the locking

tab on top of the bearing cap. |

|||

While

forming the correct bends in the tubing, you can allow the seal housing to

rotate counter-clockwise a little to make room to make the final bend

where it will go into the bulkhead body that we just installed. Now we fit

the tube for trimming. While

forming the correct bends in the tubing, you can allow the seal housing to

rotate counter-clockwise a little to make room to make the final bend

where it will go into the bulkhead body that we just installed. Now we fit

the tube for trimming. |

|||

ARB

has provided a tube that is more than long enough to take care of this

application. So we have to trim it after putting everything back into

place. A permanent marker will allow you to mark where you will have to

cut it. We suggest using a tubing cutter to make this cut, as most

anything else will deform the tube which could lead to air leaks later

on. ARB

has provided a tube that is more than long enough to take care of this

application. So we have to trim it after putting everything back into

place. A permanent marker will allow you to mark where you will have to

cut it. We suggest using a tubing cutter to make this cut, as most

anything else will deform the tube which could lead to air leaks later

on. |

|||

We

fit the tube and seal housing in its approximate finished location and

then gently bent it out of the way so we could fir the carrier into place.

When you look around inside the empty case, you can find a couple of other

places you could mount the air tube bulkhead body. I took a look at least two where we wouldn't have to drill the case. We

fit the tube and seal housing in its approximate finished location and

then gently bent it out of the way so we could fir the carrier into place.

When you look around inside the empty case, you can find a couple of other

places you could mount the air tube bulkhead body. I took a look at least two where we wouldn't have to drill the case. |

|||

But

neither of the locations allowed enough clearance between the ring and the

case for the line to go between with a margin of safety. So when all else

fails... follow the directions from the carrier manufacturer (which,

by the way, was very well laid out and detailed. Thanks ARB). With the air

line out of the way, the carrier goes back into place (to stay this

time). But

neither of the locations allowed enough clearance between the ring and the

case for the line to go between with a margin of safety. So when all else

fails... follow the directions from the carrier manufacturer (which,

by the way, was very well laid out and detailed. Thanks ARB). With the air

line out of the way, the carrier goes back into place (to stay this

time). |

|||

The

easy part is the ring side of the differential. We just reassembled it

exactly the reverse of its disassembly. Don't lock down the bearing cap

bolts until you are done with backlash adjustments later. The other side

gets a bit trickier because it has to house an airtight seal for the

locker. It starts with a small clamping plate that has been tapped for

three allen screws. The

easy part is the ring side of the differential. We just reassembled it

exactly the reverse of its disassembly. Don't lock down the bearing cap

bolts until you are done with backlash adjustments later. The other side

gets a bit trickier because it has to house an airtight seal for the

locker. It starts with a small clamping plate that has been tapped for

three allen screws. |

|||

Next

came the adjustment ring. Notice that it looks a little different than the

stock unit. Be careful when working around the extended bearing journal

because it has to be perfectly smooth and scratch free to keep the seal

air tight. Next we installed the bearing cap bolts, but, like the other

side we kept it loose enough to make the backlash adjustments needed. Next

came the adjustment ring. Notice that it looks a little different than the

stock unit. Be careful when working around the extended bearing journal

because it has to be perfectly smooth and scratch free to keep the seal

air tight. Next we installed the bearing cap bolts, but, like the other

side we kept it loose enough to make the backlash adjustments needed. |

|||

*NOTE* *NOTE*Backlash is measured with a dial indicator. The pinion must be immobilized (held perfectly still) and then the dial indicator is used to measure the amount of movement the ring gear still has. The Factory Service Manual says the measurement should be between 0.004 and 0.006 inches. The adjustment is controlled by running in one adjuster ring and running out the opposite adjuster equally. Turning the adjuster one notch changes the backlash by about 0.002 inches. |

|||

The o-rings are the most critical part of the air seal. When installed,

they create an air chamber that 'floats' on the bearing journal. The air

comes in through the seal housing and is plumbed through the journal wall

into the interior of the carrier. Give the o-rings a good coating of oil

before installing them in the seal housing. The o-rings are the most critical part of the air seal. When installed,

they create an air chamber that 'floats' on the bearing journal. The air

comes in through the seal housing and is plumbed through the journal wall

into the interior of the carrier. Give the o-rings a good coating of oil

before installing them in the seal housing. |

|||

Also

make sure the o-rings aren't twisted in the grooves. Click on the photo to

the right (you can do this with any of the photos) to get a good look at

how the two o-rings border an air channel that we talked about

earlier. Also

make sure the o-rings aren't twisted in the grooves. Click on the photo to

the right (you can do this with any of the photos) to get a good look at

how the two o-rings border an air channel that we talked about

earlier. |

|||

Sliding

the seal housing onto the bearing journal, you should use a gentle

twisting motion. Don't pinch the o-rings as they slide over the end. Pay

special attention to the notch just left of the air tube. This is where

the bearing adjuster stopper has to line up with an open notch on the

adjuster ring. See the center picture below to see it in place. Using

a small screwdriver we aligned the bolt holes in the seal with the tapped

holes in the clamping plate we installed at the top of this page. We added

the three cap screws using locktite to make sure things don't come loose

later on, but at this point we left them finger tight. Sliding

the seal housing onto the bearing journal, you should use a gentle

twisting motion. Don't pinch the o-rings as they slide over the end. Pay

special attention to the notch just left of the air tube. This is where

the bearing adjuster stopper has to line up with an open notch on the

adjuster ring. See the center picture below to see it in place. Using

a small screwdriver we aligned the bolt holes in the seal with the tapped

holes in the clamping plate we installed at the top of this page. We added

the three cap screws using locktite to make sure things don't come loose

later on, but at this point we left them finger tight.

Now here is a step often neglected but very important. This is where you bench test the system and center the seal housing all at the same time. Applying air (90 psi) to the system, and then rotating the carrier will center the seal housing. At this point we slowly tightened the cap screws to 3.5 ft.lbs. If you over tighten the cap screws you will deform the clamping plate and that could cause premature failure of the seal when the cap screws fall out. |

|||

|

This is what it should look like when it is finished. Notice how the air tube has sweeping bends and stays away from the gear teeth. The locking tab has been put in place and the unit is ready to go into the sidewinder axle we installed in the last issue. |

|||

On

the left you can see the 26 spline axle in a normal ARB side gear from

this months installation. On the right you can see how much larger the

opening is in the 27 spline side gear when we put the same shaft into it.

These side gears are a direct replacement and can be ordered separately

from your ARB distributor or already installed in a new ARB air locker

prepared by the shop you get your 27 spline shafts from. On

the left you can see the 26 spline axle in a normal ARB side gear from

this months installation. On the right you can see how much larger the

opening is in the 27 spline side gear when we put the same shaft into it.

These side gears are a direct replacement and can be ordered separately

from your ARB distributor or already installed in a new ARB air locker

prepared by the shop you get your 27 spline shafts from. |

|||

Next

issue we will show you how to convert an existing (Samurai) ARB 26 spline rear

carrier to fit the 22 spline front axle in a Samurai. That way you can

just move the ARB you spent money on last season to the front and end up

with two air lockers. Next

issue we will show you how to convert an existing (Samurai) ARB 26 spline rear

carrier to fit the 22 spline front axle in a Samurai. That way you can

just move the ARB you spent money on last season to the front and end up

with two air lockers. |

|||

|

Check out part three of this series and see how easy it is |

|||

| Source:

ARB Corporation Limited

|

03/14/2017